Product Introduction

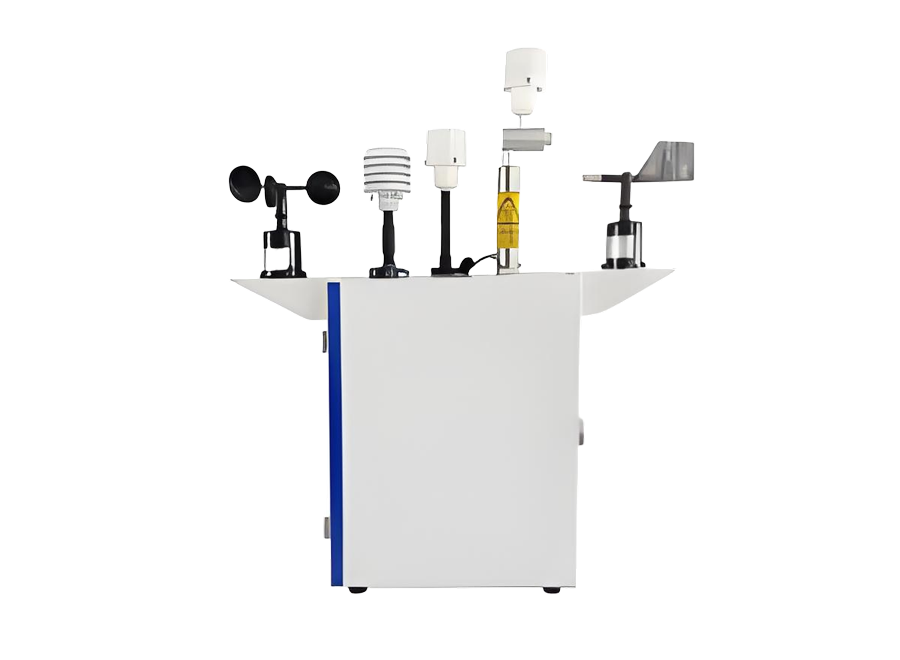

Using advanced sensor technology, internet technology, wireless communication technology, computer network technology, and electronic geographic information technology, this system achieves a 24/7 online monitoring capability and supports on-site video surveillance. Once a violating industry is detected, regulatory authorities can quickly implement corrective measures. This not only alleviates the workload of staff but also allows for immediate intervention before serious impacts occur, thereby enhancing the city's image. Users can customize the factors measured by the ZHK6180 according to their specific needs. Optional monitoring factors include standard pollutants such as ozone (O3), nitrogen dioxide (NO2), carbon monoxide (CO), sulfur dioxide (SO2), particulate matter (TSP, PM10, PM2.5), temperature, humidity, and atmospheric pressure. Additional options may include volatile organic compounds (TVOC), hydrogen sulfide (H2S), carbon dioxide (CO2), as well as noise, wind speed, wind direction, and precipitation.

Get a quoteMain Features

Calibration on-site based on traceable reference standards.

The device is equipped with a built-in constant temperature module, enabling normal operation in harsh temperature environments, ensuring the accuracy of data measurements. Utilizes high-precision, imported four-electrode sensors.

No need to replace the sampling cutter; it can simultaneously measure PM10 and PM2.5 mass concentrations.

Modular design allows for arbitrary combinations, facilitating the setting of different monitoring factors based on demand, suitable for large-scale grid deployment.

The circuit employs an industrial-grade embedded processor, capable of withstanding harsh outdoor environments, with an operational temperature range of (-30 to 70) °C.

Particulate matter sampling uses dynamic heating control to eliminate the impact of water vapor on measurement data.

Features an industrial-grade data transmission module for stable and reliable data transfer.

The system utilizes a multi-channel communication method to ensure communication under extreme conditions, guaranteeing data continuity.

Through innovation, automotive electronic communication protocols have been applied to environmental monitoring instruments, with high-reliability CAN bus communication between modules to ensure system stability.

Not only can it achieve remote data transmission, but it also allows for remote monitoring of the instrument's operational status and diagnostics for instrument malfunctions. Terminal devices can perform remote upgrades of terminal applications via an FTP server, enabling remote maintenance and ensuring users can access the latest applications and timely updates of system functions. Optional zero gas calibration module, wind speed, and wind direction modules are available.

Various parameter IP cameras can be optionally equipped to meet nighttime and visibility shooting requirements; cameras can take automatic snapshots and allow users to view in real-time.

On-site real-time data display: terminal instruments display data every 5 seconds.

An optional data service platform can display minute, hourly, and daily averages.

Reporting and analysis features can generate daily, monthly, and annual reports, as well as trend analyses.

The system supports multi-point display on a single screen and mobile terminal data queries, and can push data to display terminals.

Multiple installation methods are available based on site conditions, including bracket installation, pole mounting, and other methods.

All installation methods are secure and reliable, capable of withstanding sudden winds of up to Force 12.